| Workshop | Empennage | Wings | Fuselage | Contact |

| <-- April 2010 | June 2010 --> |

Chronological Updates, May, 2010

4 May 2010

Out of the country for another three weeks there, now I'm back with a powerful case of jetlag. Didn't want to engage in anything too complex since my brain is still somewhere over eastern Europe, so I spent some time (between three and five in the morning) fabricating the airframe ground bracket.

The wiring harness plans (OP-37?) call for putting a bolt through this piece of the battery tray and attaching a 2 AWG wire from the battery ground terminal to the bolt, thus connecting the airframe to the electrical ground system. This allows things like lights and pitot heat to be connected to ground locally rather than having to run heavy ground wires around for these high-current sources. However, because of all the accessories I'm loading into the tail cone, in particular the external power socket, I need quite a few grounds to come together here. The two coming from the external power socket and the battery are both 2 AWG, and I didn't want to try to load all of that onto one bolt.

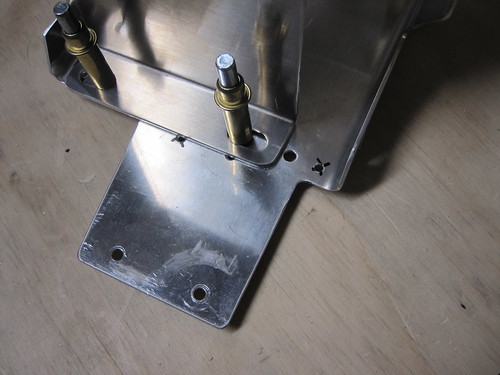

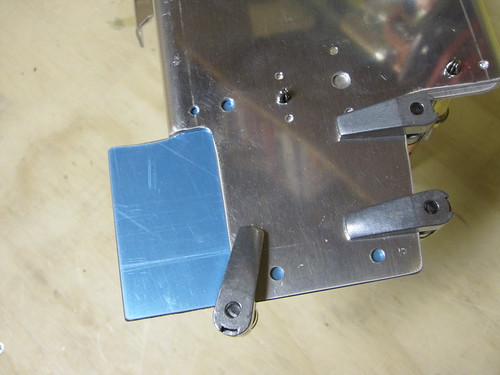

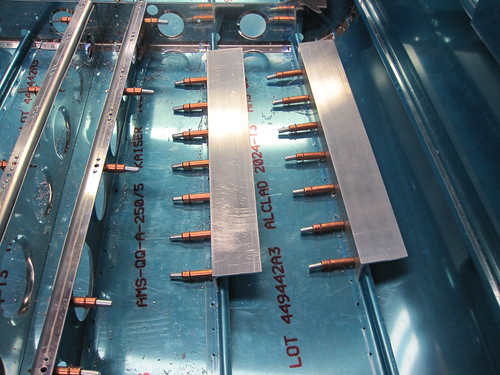

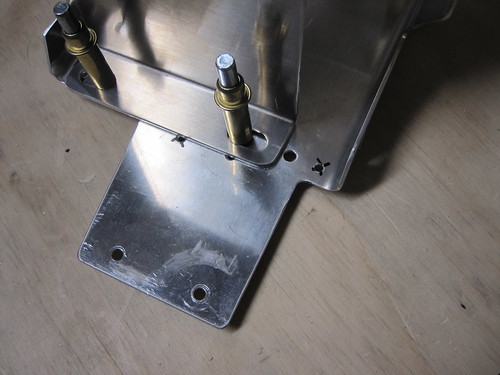

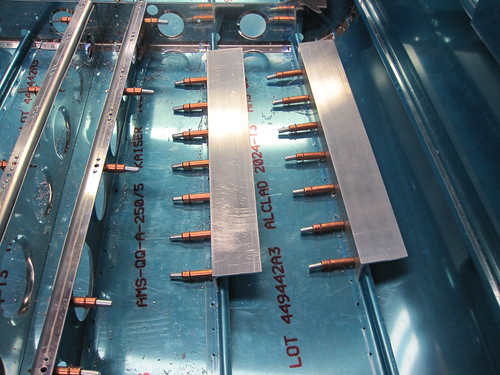

In addition, I wanted the grounding bolts to be mounted horizontally rather than the suggested vertical arrangement, which I think will make my wiring look a little cleaner in this area. I have seen other builders put a piece of aluminum angle here and bolt into that, so I started designing something like that. Another design goal of mine was to be able to use the original forward-left battery hold-down bolt hole to help with the new battery box. As you can see from the photo, above, the old hole is right up against the edge of the battery box, so I wouldn't be able to fit a washer on there. I considered grinding down some washers to fit that space, but instead decided to just extend the grounding bracket to include a tab that sticks out into this space. Using metal of the same thickness, I can now put a washer and bolt into that hole and it would clamp down the box and take advantage of the rib rail beneath the original hole (the new hole just has the tray and no support underneath). With this in mind, I cut out a piece of 0.063" aluminum (the closest sheet thickness I could find to the thickness of the battery box) that looks like this:

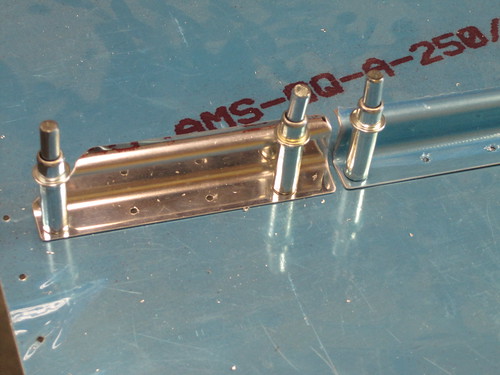

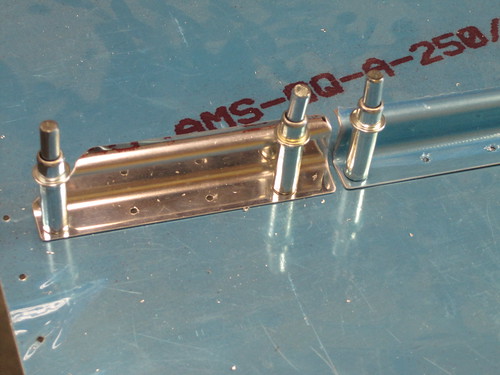

The wide tab on the left side (right in this image) will get bent upwards and the grounding bolts will attach to this. Looking at the bottom of the battery tray with the new piece clamped in place, you can see the three bolt holes that they share:

The small hole in the upper-left of this photo will not be used and thus will not be match-drilled into the grounding bracket. The two holes at the bottom of the photo are for the bolts that attach the battery tray to the F-1006 frame. After match-drilling these three bolt holes, the bracket looks like this:

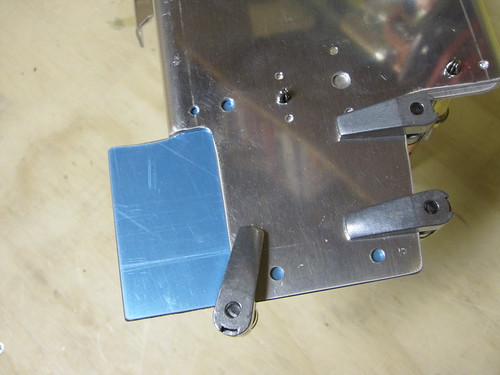

Because the battery tray must be removable from the completed plane in order to allow maintenance on the elevator pushrod system, there can be no rivets that attach the tray to any of the other stock airframe. I wanted to rivet the grounding bracket to the tray, however, to increase the electrical connectivity between the two. To achieve this, I drilled six holes between the two parts for 1/8" rivets in a spot that was clear of the underlaying rib rail and F-1006 tab. I also used a hand-seamer to put a 90° bend in the bracket to match the adjacent flange on the battery tray.

Most of the grounding bracket won't get primed so that there is a good electrical connection between the bolt heads and the bracket. Before priming the rest of the battery tray (but after alodining both parts), I will rivet these six holes with AN470 hardware. Then I'll mask the parts that don't get primer and spray it down.

The next task was to drill some holes for anchor nuts that would hold the actual grounding bolts, but I had a brain wave at the last moment that caused me to change my design a bit. I was thinking of two large AN4 bolts for the battery and external power connector 2 AWG lines, pluse a third AN3 bolt for the assorted low-current ground returns that come here (overhead console lighting, external power relay control, etc.). However, having a bunch of wires returning to a threaded post like that, each with its own ring termianl, is going to get ugly fast. Instead, why not use a small "forest of tabs" style grounding buss attached right to the bracket. SteinAir sells a nice 10-tab version that is only a couple inches long. I've got one on order now, and when it arrives I'll figure out a way to attach it to the base of the grounding bracket, then I can route up to 10 small-gauge grounding wires here cleanly. Until it arrives, this piece is on standby.

6 May 2010

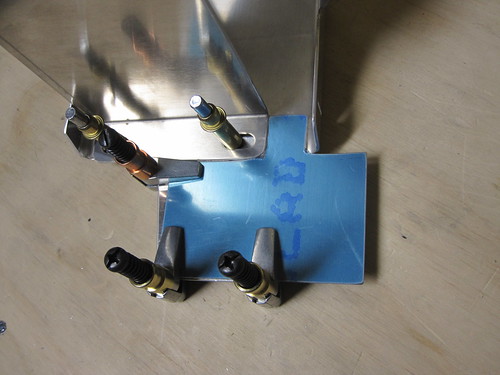

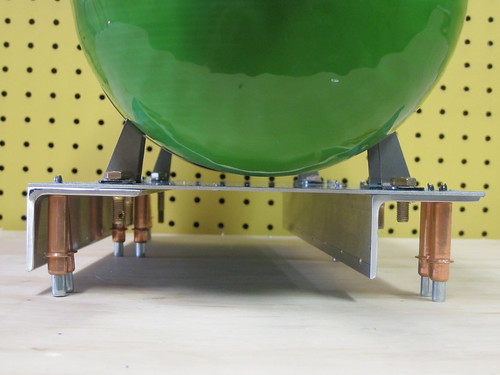

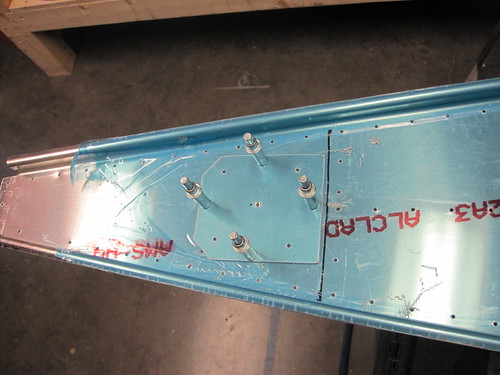

Today I knocked out most of the oxygen tank mount hardware. I had been planning to put the tank on the left-side wall, attaching it to the D and E stiffeners. However, I noticed that the documentation for the tank clamps indicates that it supports considerably less side-loading than it does up-and-down loading. And since the highest forces likely to be encountered are landing shocks (oriented in the vertical axis), I wanted to orient the tank such that the clamp feet were on the bottom (or top...) of the tank. As a result, I moved my design to the work with the outer two J-stiffeners on the left side of the bottom skin of the tail cone, in the bay between the F-1006 and F-1007 frames.

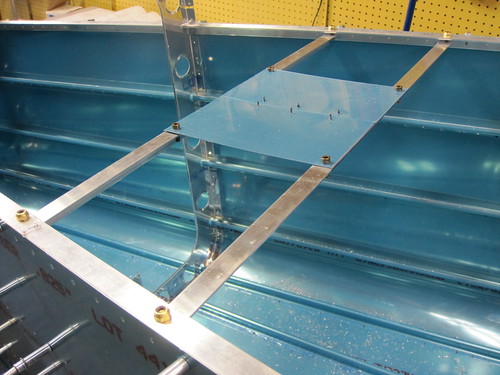

The first step was to fabricate two 14" lengths of 1.5" x 2" x 0.125" angle aluminum. The reason I used such a large angle was because the stiffeners aren't parallel. Thus, if I align the feet with an edge on one angle bracket, the feet will be skewed on the other and require a larger landing. I drilled seven holes, every two inches, a quarter inch above the edge of the shorter side of each angle. Then I used my right-angle drill kit to match-drill these holes into the J-stiffener flanges.

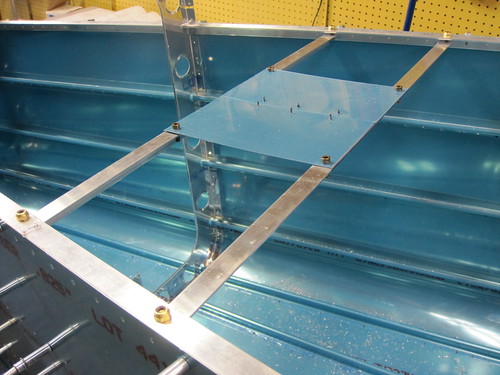

When I cleco'd the angle brackets into place, I could see that the J-stiffener flanges were not perpendicular to the bottom skin. As a result, the two "horizontal" parts were not co-planar.

This wasn't a big problem, because a gentle push on the horizontal parts would bend the stiffener flange slightly and result in good alignment between the two brackets. I decided to fashion a plate to connect the two angle brackets and ensure that they were laying co-planar. This worked like a charm and didn't impose too much stress on the J-stiffeners.

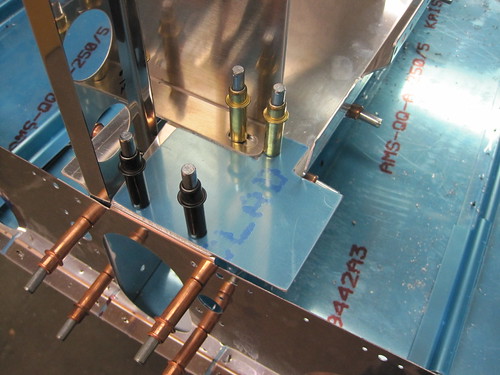

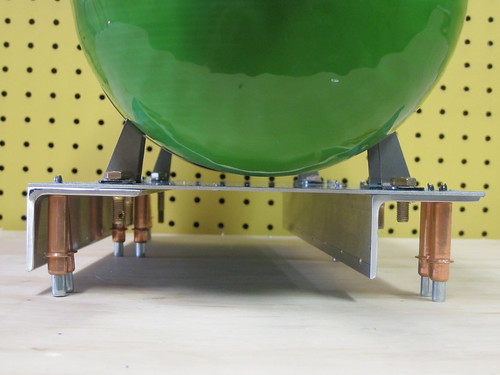

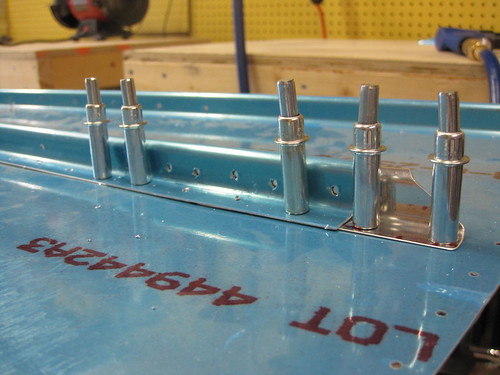

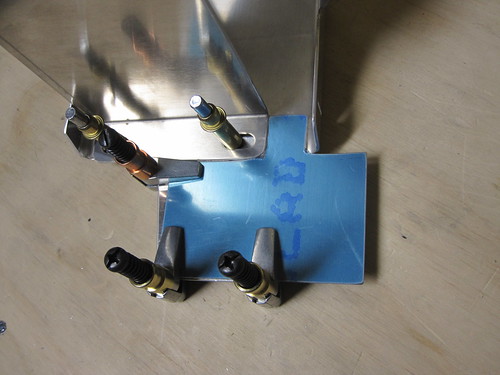

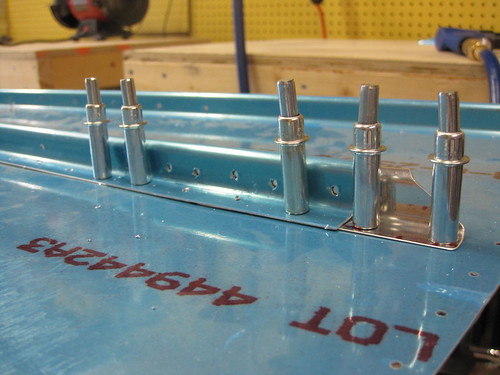

I added a series of twelve 1/8" holes for eventual rivets between the top plate and the angle brackets. From here, it was simply a matter of match-drilling the feet of the oxygen tank clamp into the angle brackets and top plate. Eight 1/4" holes later, the tank could be bolted onto to the brackets.

In the picture above, the bolts are just stuck through the holes with no nuts or anything. Also, they are all different lengths because I haven't bought hardware for this yet. My plan is to put K1000-4 nutplates on the underside of the angle brackets to capture the eight bolts. AN4-5A bolts should be perfect.

Technically, with the clamp feet bolted into the nutplates, the twelve rivet holes become redundant. Also, once rivets are put in place there, the top plate is no longer removable. On the off chance that I decide to run some wires underneath this assembly and want to attach an adel clamp to the bottom side of the top plate, I will probably leave these rivet holes empty at least until wiring is complete, if not forever. They were just there to hold everything square with clecos while I drilled out the bolt holes.

9 May 2010

Big day today, culminating with the long-awaited return to following the plans after having finished fabrication tasks for the custom accessories.

First up was to match-drill a mounting bracket for the ELT into the right-side stiffeners. This was a quick job. I don't have the ELT yet (it is still on backorder and has been for many months), but when I get it I can just figure out how to get its quick-release plate mounted to this bracket. Mounting the bracket to the plane is just a matter of eight blind rivets. Now that the holes are matched drilled, the ELT mounting task can be put off essentially indefinitely without affecting the critical path.

Along the same lines, I don't yet have magnetometers to mount, but I know I want to keep them far away from anything with ferrous metals in it. The all-aluminum tail cone is a great place for this, so I fabricated a little shelf in the middle of the tail cone that will hold the magnetometer(s) when I get around to choosing and buying some. All of the attachment hardware is brass so as not to affect the magnetic field in the area of the sensors. The angle-aluminum cross bars will get mounted now, the shelf will go on when the magnetometers arrive, allowing me to customize how they will be attached.

There will be a conduit running down the top center of the tail cone to service the magnetometers and the ELT antenna, and it is supported by lightening hole wire tie brackets in the F-1007 and F-1008 frames. However, these frames are somewhat far apart and I wanted additional support for the conduit, so I made a couple of little hangers that span the A and B stiffeners and have a hole in the middle for an adel clamp to be mounted. Nothing fancy.

Next up was a doubler for the ELT antenna. I decided to mount it on the top of the tail cone, just aft of the F-1008 frame and just left of the A stiffener. Unfortunately the new E-04 antenna cannot be mounted under the empennage fairing like the old E-01 one could. So this is going to be ugly... but with the added capabilities of the 406MHz satellite support, perhaps it'll actually be useful and not just a compliance checkbox... Anyway, the antenna needed a doubler. So I cut out a two inch square piece of sheet stock and drilled a circular pattern of holes in it. Then I used this as a template to match drill the holes into the top skin.

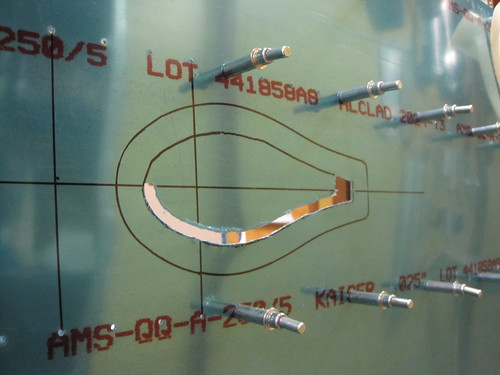

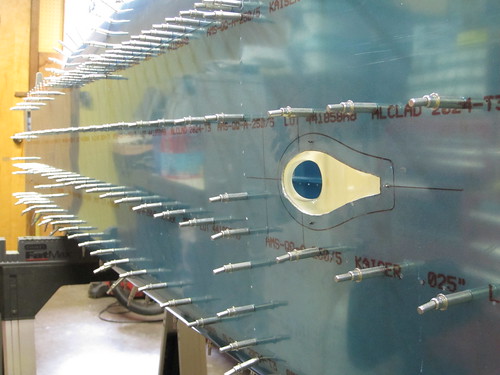

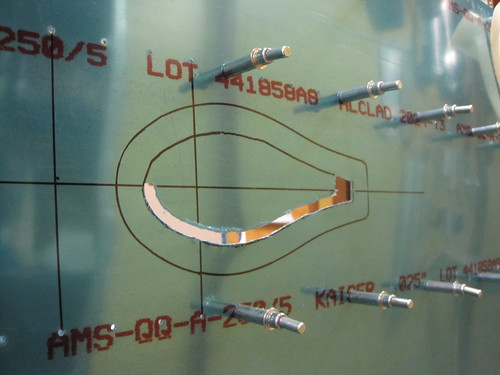

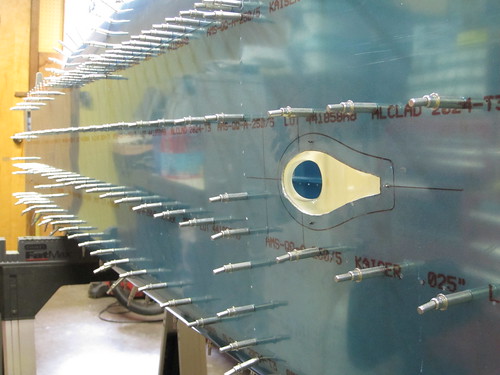

The last of the custom fabrication tasks was to cut holes for the NACA inlets on the sides of the tail cone. I made a template for the hole out of cardboard, then traced the location onto the skins I made the long axis of the intake parallel to the longerons, rather than the adjacent stiffeners. To cut out the hole, I drilled a 1/2" pilot hole at the forward end, then used a nibbler to trace the perimeter of the hole. Then I went at the edges with a file, a dremel sanding drum, and a scotch bright pad. Here's the nibbler in action:

And here's the final result:

With that done, it was (finally) time to return to the plans and continue working towards a finished tail cone. The next step says, "disassemble all parts." One lingering question remained, however, that was best answered with the tail cone still assembled. The fully-assembled tail cone is too big to fit out the door. So how much of it can I rivet together and still squeeze it out the shop door and into the garage? To test this, I took off the F-1006 bulkhead as it is clearly too large to fit through my door in any orientation. I also moved all of the aft clecos from the bottom skin to the inside of the tail cone, thus minimizing the total height of the piece (it is less tall than it is wide, so I'll try to move it out the door on its side).

In this configuration, my friend Mike and I were just able to get it out the door with about 1/4" to spare on either side. This is great news, since I will be able to do almost all of the tail cone riveting in the shop, only having to move into the garage to do the top aft skin. So I went ahead and moved what you see above into the garage and then started harvesting pieces off of it for the deburring/dimpling/countersinking phase of the process. I'm really not looking forward to the 10,000 or so hole deburrs that I need to do here (~2500 holes, each one joins at least two pieces, each hole in each piece has two sides...), but it is great to be back on the plans and making forward progress again. I managed to move several of the smaller parts onto the pile of things ready to primed (finally, some color changes in the monthly progress image!).

22 May 2010

Up until today, just little bits of deburring and dimpling has been going on every now and then. Now I have a live-inslave labor summer student who agreed to help with some of the

dull deburring tasks, so today we set about making a dent in the sizeable deburring requirements

of the tail cone.

At this point all of the small parts of the tail cone are done per the plans up the point of priming. All of the stiffeners except for the two F stiffeners are also ready for primer (the F pair need some modifications due my cutting them short awhile back). All frames and bulkheads are now ready for primer as well (with the exception of a few custom holes I'm going to drill for lightening hole tie-down brackets and adel clamps). This leaves only the skins to deal with.

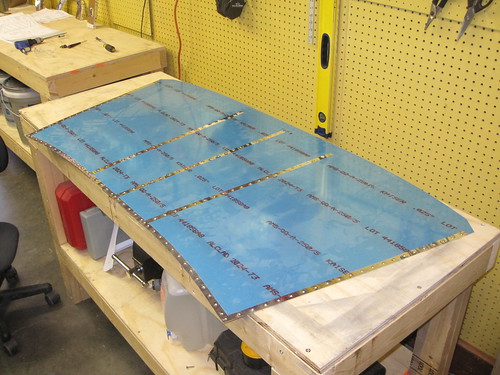

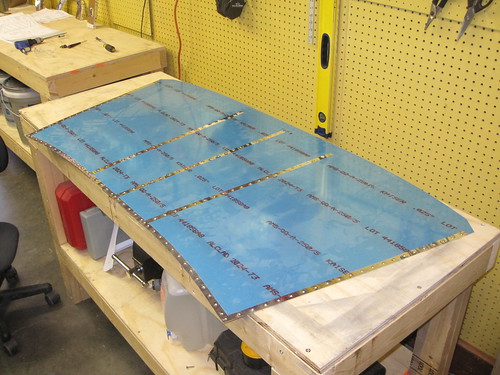

Today we managed to knock out all of the deburring and dimpling on both top skins and the right side skin. Here is a shot of the completed forward top skin:

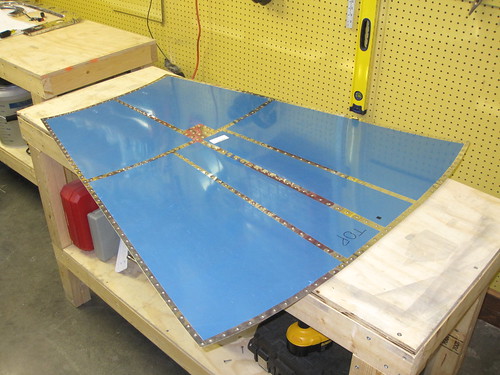

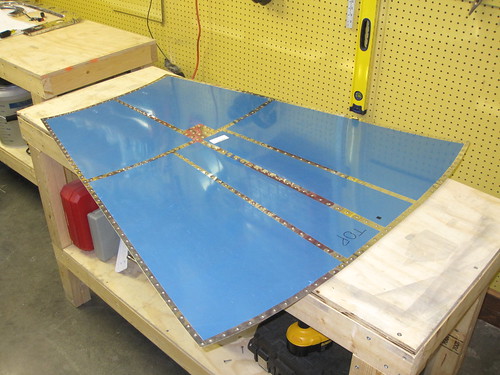

And here is the aft top skin:

You can see in this picture where I am installing the doubler for the ELT antenna. It is just aft of the left-side B stiffener. I made a 2" circle of holes where rivets will join the doubler to the skin. A pilot center hole is also present, though it will eventually be widened to accomodate the antenna's connector.

Here is a picture of the side skin all dimpled up, along with one of my cats:

Through some careful planning and a lot of rotating the part around, Jeremy and I were able to do all of the holes in the side skin with the DRDT-2 dimpler except the 20 or so holes that are located on the radiused bend. These I did one by one with the pop riveter and its associated dimple die set. Takes about an order of magnitude longer per hole, but given how few of them there were it wasn't a problem.

Hopefully tomorrow I can knock out the other side skin and start doing some of the remaining work that is required on the bottom skins and F-stiffeners. Once those are done, it'll be time for chemistry once again! And then, the fun part. Riveting.

23 May 2010

Spent all day today working on the plane, trying to push through the remainder of the deburring and dimpling ennui.

Knocked out the left side skin in the morning without any problems.

This left only the F-stiffeners and the bottom skin remaining in my pile of incomplete stock parts. As you'll recall from way back when I started the tail cone, I biffed the cuts on the F stiffeners and made them both too short by about an inch. Rather than re-order the parts and start over, I decided to just fashion some extenders for the stiffeners. I cut off another three inches from each one, then made an extension of each so that the two parts laid end-to-end would be the same length as the original stiffener was meant to be.

Next, I laid another piece of stiffener stock over both parts, match drilled all of the holes through the stiffeners and skins, and added some additional holes through the flanges of the stiffener stock so that the three pieces were held together firmly in two dimensions.

Next on the hit parade, I made a doubler plate for a possible future NAV antenna on the underside of the aft end of the tail cone. This essentially just like the one Tim Olson put on his plane. When I decide to outfit the plane for IFR, this will be a great out-of-the-way spot for a good VOR/LOC/GS antenna.

Next up was cable and conduit management hardware. I added a lot of holes for adel clamps and lightening hole wire tie anchors. Here is a shot of the hardware for bringing the top-side aft tail cone electronics (vertical stabilizer cable bundle and elevator trim servo bundle) down and across to where the bottom conduit will terminate:

Here's another shot showing the hardware that will manage the static air lines and the terminus of the upper conduit:

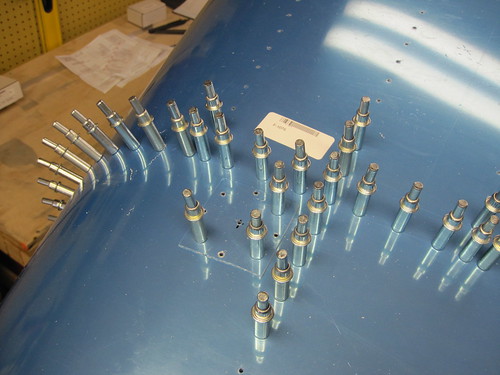

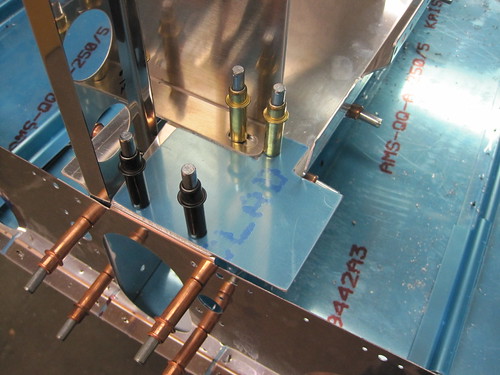

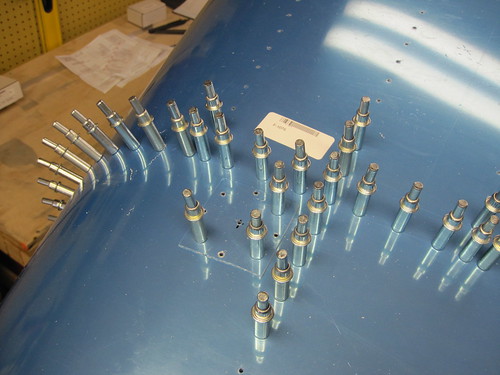

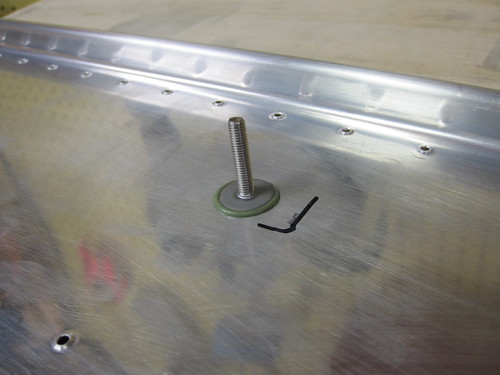

I had been spending a lot of time trying to figure out how to attach my forest-of-tabs grounding block to my grounding plate near the battery. There wasn't a lot of room because I only had the idea to add tabs here after I had fabricated the plate and drilled a bunch of holes in it. What I ended up with was attaching the tabs to the plate via CS4-4 countersunk blind rivets from the bottom side. I countersunk four big holes into the bottom of the plate for this purpose:

And here's what the tabs will look like after I rivet them on (I'm waiting until the part is Alodined before I rivet the brass on):

With that out of the way, I was done with drilling ops for the day and went back to deburring and dimpling. The only piece left was the bottom tail cone skin. I made quick work of it:

You can see af the narrow end where the circle of rivets is that will secure the NAV antenna doubler. The hole in the center is just a pilot hole and will eventually be enlared to support an antenna.

The last thing I did today was attach three Click Bond threaded studs to the bottom skin. These are for attaching adel clamps that will support the bottom conduit between frames and bulkheads. I'm really impressed with how easy these parts are to attach and how strong the adhesive seems to be.

The only things on my TODO list before I can start the alumiprep/alodine/akzo chemistry funtime are:

Out of the country for another three weeks there, now I'm back with a powerful case of jetlag. Didn't want to engage in anything too complex since my brain is still somewhere over eastern Europe, so I spent some time (between three and five in the morning) fabricating the airframe ground bracket.

The wiring harness plans (OP-37?) call for putting a bolt through this piece of the battery tray and attaching a 2 AWG wire from the battery ground terminal to the bolt, thus connecting the airframe to the electrical ground system. This allows things like lights and pitot heat to be connected to ground locally rather than having to run heavy ground wires around for these high-current sources. However, because of all the accessories I'm loading into the tail cone, in particular the external power socket, I need quite a few grounds to come together here. The two coming from the external power socket and the battery are both 2 AWG, and I didn't want to try to load all of that onto one bolt.

In addition, I wanted the grounding bolts to be mounted horizontally rather than the suggested vertical arrangement, which I think will make my wiring look a little cleaner in this area. I have seen other builders put a piece of aluminum angle here and bolt into that, so I started designing something like that. Another design goal of mine was to be able to use the original forward-left battery hold-down bolt hole to help with the new battery box. As you can see from the photo, above, the old hole is right up against the edge of the battery box, so I wouldn't be able to fit a washer on there. I considered grinding down some washers to fit that space, but instead decided to just extend the grounding bracket to include a tab that sticks out into this space. Using metal of the same thickness, I can now put a washer and bolt into that hole and it would clamp down the box and take advantage of the rib rail beneath the original hole (the new hole just has the tray and no support underneath). With this in mind, I cut out a piece of 0.063" aluminum (the closest sheet thickness I could find to the thickness of the battery box) that looks like this:

The wide tab on the left side (right in this image) will get bent upwards and the grounding bolts will attach to this. Looking at the bottom of the battery tray with the new piece clamped in place, you can see the three bolt holes that they share:

The small hole in the upper-left of this photo will not be used and thus will not be match-drilled into the grounding bracket. The two holes at the bottom of the photo are for the bolts that attach the battery tray to the F-1006 frame. After match-drilling these three bolt holes, the bracket looks like this:

Because the battery tray must be removable from the completed plane in order to allow maintenance on the elevator pushrod system, there can be no rivets that attach the tray to any of the other stock airframe. I wanted to rivet the grounding bracket to the tray, however, to increase the electrical connectivity between the two. To achieve this, I drilled six holes between the two parts for 1/8" rivets in a spot that was clear of the underlaying rib rail and F-1006 tab. I also used a hand-seamer to put a 90° bend in the bracket to match the adjacent flange on the battery tray.

Most of the grounding bracket won't get primed so that there is a good electrical connection between the bolt heads and the bracket. Before priming the rest of the battery tray (but after alodining both parts), I will rivet these six holes with AN470 hardware. Then I'll mask the parts that don't get primer and spray it down.

The next task was to drill some holes for anchor nuts that would hold the actual grounding bolts, but I had a brain wave at the last moment that caused me to change my design a bit. I was thinking of two large AN4 bolts for the battery and external power connector 2 AWG lines, pluse a third AN3 bolt for the assorted low-current ground returns that come here (overhead console lighting, external power relay control, etc.). However, having a bunch of wires returning to a threaded post like that, each with its own ring termianl, is going to get ugly fast. Instead, why not use a small "forest of tabs" style grounding buss attached right to the bracket. SteinAir sells a nice 10-tab version that is only a couple inches long. I've got one on order now, and when it arrives I'll figure out a way to attach it to the base of the grounding bracket, then I can route up to 10 small-gauge grounding wires here cleanly. Until it arrives, this piece is on standby.

6 May 2010

Today I knocked out most of the oxygen tank mount hardware. I had been planning to put the tank on the left-side wall, attaching it to the D and E stiffeners. However, I noticed that the documentation for the tank clamps indicates that it supports considerably less side-loading than it does up-and-down loading. And since the highest forces likely to be encountered are landing shocks (oriented in the vertical axis), I wanted to orient the tank such that the clamp feet were on the bottom (or top...) of the tank. As a result, I moved my design to the work with the outer two J-stiffeners on the left side of the bottom skin of the tail cone, in the bay between the F-1006 and F-1007 frames.

The first step was to fabricate two 14" lengths of 1.5" x 2" x 0.125" angle aluminum. The reason I used such a large angle was because the stiffeners aren't parallel. Thus, if I align the feet with an edge on one angle bracket, the feet will be skewed on the other and require a larger landing. I drilled seven holes, every two inches, a quarter inch above the edge of the shorter side of each angle. Then I used my right-angle drill kit to match-drill these holes into the J-stiffener flanges.

When I cleco'd the angle brackets into place, I could see that the J-stiffener flanges were not perpendicular to the bottom skin. As a result, the two "horizontal" parts were not co-planar.

This wasn't a big problem, because a gentle push on the horizontal parts would bend the stiffener flange slightly and result in good alignment between the two brackets. I decided to fashion a plate to connect the two angle brackets and ensure that they were laying co-planar. This worked like a charm and didn't impose too much stress on the J-stiffeners.

I added a series of twelve 1/8" holes for eventual rivets between the top plate and the angle brackets. From here, it was simply a matter of match-drilling the feet of the oxygen tank clamp into the angle brackets and top plate. Eight 1/4" holes later, the tank could be bolted onto to the brackets.

In the picture above, the bolts are just stuck through the holes with no nuts or anything. Also, they are all different lengths because I haven't bought hardware for this yet. My plan is to put K1000-4 nutplates on the underside of the angle brackets to capture the eight bolts. AN4-5A bolts should be perfect.

Technically, with the clamp feet bolted into the nutplates, the twelve rivet holes become redundant. Also, once rivets are put in place there, the top plate is no longer removable. On the off chance that I decide to run some wires underneath this assembly and want to attach an adel clamp to the bottom side of the top plate, I will probably leave these rivet holes empty at least until wiring is complete, if not forever. They were just there to hold everything square with clecos while I drilled out the bolt holes.

9 May 2010

Big day today, culminating with the long-awaited return to following the plans after having finished fabrication tasks for the custom accessories.

First up was to match-drill a mounting bracket for the ELT into the right-side stiffeners. This was a quick job. I don't have the ELT yet (it is still on backorder and has been for many months), but when I get it I can just figure out how to get its quick-release plate mounted to this bracket. Mounting the bracket to the plane is just a matter of eight blind rivets. Now that the holes are matched drilled, the ELT mounting task can be put off essentially indefinitely without affecting the critical path.

Along the same lines, I don't yet have magnetometers to mount, but I know I want to keep them far away from anything with ferrous metals in it. The all-aluminum tail cone is a great place for this, so I fabricated a little shelf in the middle of the tail cone that will hold the magnetometer(s) when I get around to choosing and buying some. All of the attachment hardware is brass so as not to affect the magnetic field in the area of the sensors. The angle-aluminum cross bars will get mounted now, the shelf will go on when the magnetometers arrive, allowing me to customize how they will be attached.

There will be a conduit running down the top center of the tail cone to service the magnetometers and the ELT antenna, and it is supported by lightening hole wire tie brackets in the F-1007 and F-1008 frames. However, these frames are somewhat far apart and I wanted additional support for the conduit, so I made a couple of little hangers that span the A and B stiffeners and have a hole in the middle for an adel clamp to be mounted. Nothing fancy.

Next up was a doubler for the ELT antenna. I decided to mount it on the top of the tail cone, just aft of the F-1008 frame and just left of the A stiffener. Unfortunately the new E-04 antenna cannot be mounted under the empennage fairing like the old E-01 one could. So this is going to be ugly... but with the added capabilities of the 406MHz satellite support, perhaps it'll actually be useful and not just a compliance checkbox... Anyway, the antenna needed a doubler. So I cut out a two inch square piece of sheet stock and drilled a circular pattern of holes in it. Then I used this as a template to match drill the holes into the top skin.

The last of the custom fabrication tasks was to cut holes for the NACA inlets on the sides of the tail cone. I made a template for the hole out of cardboard, then traced the location onto the skins I made the long axis of the intake parallel to the longerons, rather than the adjacent stiffeners. To cut out the hole, I drilled a 1/2" pilot hole at the forward end, then used a nibbler to trace the perimeter of the hole. Then I went at the edges with a file, a dremel sanding drum, and a scotch bright pad. Here's the nibbler in action:

And here's the final result:

With that done, it was (finally) time to return to the plans and continue working towards a finished tail cone. The next step says, "disassemble all parts." One lingering question remained, however, that was best answered with the tail cone still assembled. The fully-assembled tail cone is too big to fit out the door. So how much of it can I rivet together and still squeeze it out the shop door and into the garage? To test this, I took off the F-1006 bulkhead as it is clearly too large to fit through my door in any orientation. I also moved all of the aft clecos from the bottom skin to the inside of the tail cone, thus minimizing the total height of the piece (it is less tall than it is wide, so I'll try to move it out the door on its side).

In this configuration, my friend Mike and I were just able to get it out the door with about 1/4" to spare on either side. This is great news, since I will be able to do almost all of the tail cone riveting in the shop, only having to move into the garage to do the top aft skin. So I went ahead and moved what you see above into the garage and then started harvesting pieces off of it for the deburring/dimpling/countersinking phase of the process. I'm really not looking forward to the 10,000 or so hole deburrs that I need to do here (~2500 holes, each one joins at least two pieces, each hole in each piece has two sides...), but it is great to be back on the plans and making forward progress again. I managed to move several of the smaller parts onto the pile of things ready to primed (finally, some color changes in the monthly progress image!).

22 May 2010

Up until today, just little bits of deburring and dimpling has been going on every now and then. Now I have a live-in

At this point all of the small parts of the tail cone are done per the plans up the point of priming. All of the stiffeners except for the two F stiffeners are also ready for primer (the F pair need some modifications due my cutting them short awhile back). All frames and bulkheads are now ready for primer as well (with the exception of a few custom holes I'm going to drill for lightening hole tie-down brackets and adel clamps). This leaves only the skins to deal with.

Today we managed to knock out all of the deburring and dimpling on both top skins and the right side skin. Here is a shot of the completed forward top skin:

And here is the aft top skin:

You can see in this picture where I am installing the doubler for the ELT antenna. It is just aft of the left-side B stiffener. I made a 2" circle of holes where rivets will join the doubler to the skin. A pilot center hole is also present, though it will eventually be widened to accomodate the antenna's connector.

Here is a picture of the side skin all dimpled up, along with one of my cats:

Through some careful planning and a lot of rotating the part around, Jeremy and I were able to do all of the holes in the side skin with the DRDT-2 dimpler except the 20 or so holes that are located on the radiused bend. These I did one by one with the pop riveter and its associated dimple die set. Takes about an order of magnitude longer per hole, but given how few of them there were it wasn't a problem.

Hopefully tomorrow I can knock out the other side skin and start doing some of the remaining work that is required on the bottom skins and F-stiffeners. Once those are done, it'll be time for chemistry once again! And then, the fun part. Riveting.

23 May 2010

Spent all day today working on the plane, trying to push through the remainder of the deburring and dimpling ennui.

Knocked out the left side skin in the morning without any problems.

This left only the F-stiffeners and the bottom skin remaining in my pile of incomplete stock parts. As you'll recall from way back when I started the tail cone, I biffed the cuts on the F stiffeners and made them both too short by about an inch. Rather than re-order the parts and start over, I decided to just fashion some extenders for the stiffeners. I cut off another three inches from each one, then made an extension of each so that the two parts laid end-to-end would be the same length as the original stiffener was meant to be.

Next, I laid another piece of stiffener stock over both parts, match drilled all of the holes through the stiffeners and skins, and added some additional holes through the flanges of the stiffener stock so that the three pieces were held together firmly in two dimensions.

Next on the hit parade, I made a doubler plate for a possible future NAV antenna on the underside of the aft end of the tail cone. This essentially just like the one Tim Olson put on his plane. When I decide to outfit the plane for IFR, this will be a great out-of-the-way spot for a good VOR/LOC/GS antenna.

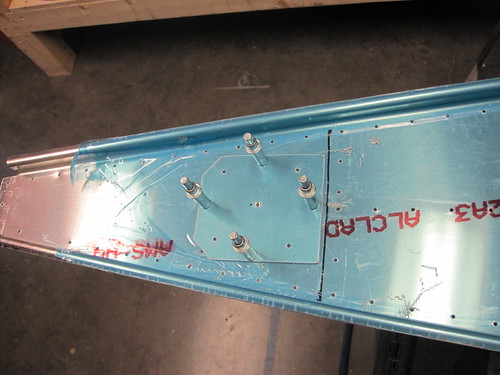

Next up was cable and conduit management hardware. I added a lot of holes for adel clamps and lightening hole wire tie anchors. Here is a shot of the hardware for bringing the top-side aft tail cone electronics (vertical stabilizer cable bundle and elevator trim servo bundle) down and across to where the bottom conduit will terminate:

Here's another shot showing the hardware that will manage the static air lines and the terminus of the upper conduit:

I had been spending a lot of time trying to figure out how to attach my forest-of-tabs grounding block to my grounding plate near the battery. There wasn't a lot of room because I only had the idea to add tabs here after I had fabricated the plate and drilled a bunch of holes in it. What I ended up with was attaching the tabs to the plate via CS4-4 countersunk blind rivets from the bottom side. I countersunk four big holes into the bottom of the plate for this purpose:

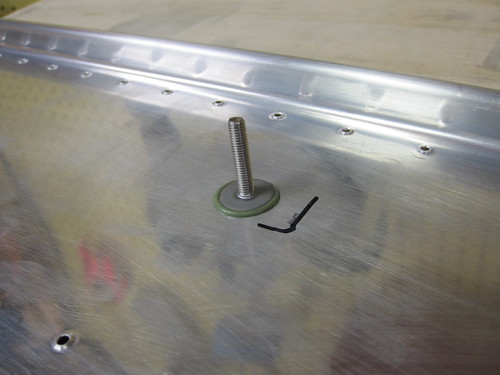

And here's what the tabs will look like after I rivet them on (I'm waiting until the part is Alodined before I rivet the brass on):

With that out of the way, I was done with drilling ops for the day and went back to deburring and dimpling. The only piece left was the bottom tail cone skin. I made quick work of it:

You can see af the narrow end where the circle of rivets is that will secure the NAV antenna doubler. The hole in the center is just a pilot hole and will eventually be enlared to support an antenna.

The last thing I did today was attach three Click Bond threaded studs to the bottom skin. These are for attaching adel clamps that will support the bottom conduit between frames and bulkheads. I'm really impressed with how easy these parts are to attach and how strong the adhesive seems to be.

The only things on my TODO list before I can start the alumiprep/alodine/akzo chemistry funtime are:

- Scuff and clean the inner surfaces of the skins (bottom skin already done).

- Bond the static air ports in place with ProSeal.

- Bond the NACA vents in place with ProSeal.

| <-- April 2010 | June 2010 --> |